Studied under the god of knives, R.W. Loveless

Since its founding in 1946, Fukuda Hamono has focused on producing high-end knives for export, and has always pursued world-class knives. TAK FUKUTA, the second-generation president of Fukuda Hamono, began studying under R.W. Loveless, an American known as the god of knives, in 1978, and became the first Japanese person to become a member of the American Knife Makers Guild. Currently, Kazuhiro, the third-generation president, continues to conduct field tests and pursue the creation of knives that are useful tools for everyday life.

The key is the "crimping" done by the craftsman

"Custom knives" are not mass-produced, but are individually handcrafted by artisans. The defining feature of Fukuda Hamono's products is the artisan's hand-crimping. Most conventional knives are attached with glue rather than crimping, but glue can easily come loose over time. However, to enhance durability, Fukuda Hamono drills holes in fragile materials like mother of pearl and turquoise, inserts pins into the holes, and hammers them into place—a technique that could easily break with a single misstep. This "crimping" technique securely secures the knives in place, ensuring their long-lasting use.

Furthermore, the blades are made from the same high-quality steel used in hunting knives, resulting in exceptionally sharp and durable knives.

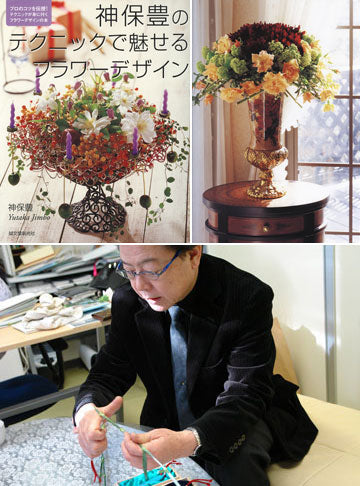

This florist knife is also recommended by Yutaka Jinbo, a leading expert in flower arranging in Japan!

Yutaka Jinbo: "I think this is an incredible florist's knife, the likes of which have never been seen before in the floral industry.

With scissors, you have to put down each time you put a flower in, but with a knife, you hold the handle between your fingers while arranging the flower, which speeds up flower arranging. It's easy to remove thorns, and the wide cut allows the flowers to absorb water more easily.

This florist's knife is highly acclaimed even by professionals for its sharpness, its intricate design, which stops the blade at a 90-degree angle, its ease of grip, weight, ease of use, and beautiful design. I believe this is a florist's knife of a quality that could only be achieved by a specialized knife manufacturer." Yutaka Jinbo

... Head of the "Cosmos Flower Design School," CEO of the flower shop "Cosmos," and Doctor of Arts. As a "professional educator for florist professionals," he provides technical instruction, and continues to engage in a wide range of activities, including demonstrations both domestically and internationally and supporting events featuring the world's top floral artists. His main publications include "Flower Designs with the Techniques of Yutaka Jinbo" (Seibundo Shinkosha, Photography)

A tip from Jinbo Yutaka!

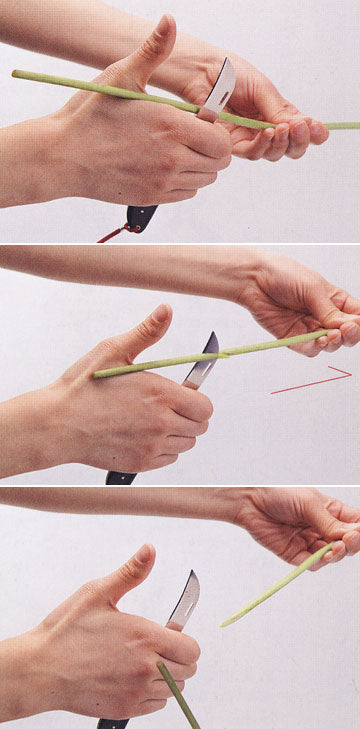

When cutting flower stems with a florist's knife, keep the knife still and pull the stem forward as you place the blade. This is similar to peeling an apple without moving the knife.

How to hold a florist's knife

: 1. Hold the base of the spine of the blade with the first joint of your index finger and grip the handle with your middle, ring, and little fingers.

2. Point your thumb up and make it parallel to the blade of the florist's knife.

Cut diagonally to create a wider cut surface on the stem or branch!

1. Hold the stem in one hand.

2. Place the stem between the blade of the florist's knife and your thumb and place the blade diagonally against the stem.

3. Keep the florist's knife still and pull the stem forward as you cut.

How a florist knife is made.

Fukuda Hamono's florist knives are not mass-produced, but are individually handcrafted by artisans.

(1) Material Selection, Cutting, Drilling, and Stretching

The material is AUS-8 stainless steel, known for its sharpness and durability.

Each component is cut from the steel, drilled, and stretched to correct any bends.

(2) Flat Grinding and Hardening

The components are polished to a consistent thickness, and then hardened at high temperatures to increase hardness.

(3) Plowing and Sharpening

The blade is thinned to make it easier to cut, then sharpened to create a clean blade surface.

(4) Mechanism and Crimping

After assembling the components, a hole is drilled in the material, a pin is inserted through the hole, and both ends of the pin are hammered to expand, firmly securing the blade and crimping it. Compared to standard bonding, crimping, which significantly improves the strength of the knife, is Fukuda's most important process. It's a technique that requires expert control of force, as even a single misstep can cause the knife to break, depending on the material.

(5) Sanding, Polishing, Sharpening, Inspection, and Adjustment

Each handle is carefully inspected, carved and rounded for a comfortable grip, and polished to a glossy finish. Finally, the blade is placed on a whetstone to ensure smooth opening and closing, and then the final finishing touches are made.

A word from the craftsman

We are committed to creating knives that combine design, ease of use, and durability as tools useful in daily life, such as for flowers, camping, and hunting. It is said that knives made with such care are rare even in the world. We hope that you will find them useful in a wide range of everyday life!