This pot has a spout that allows for good drainage, making it ideal for drip brewing.

The inside of the pot has a strainer where the body and spout join, so you can put tea leaves directly into the pot.

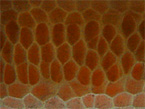

Copper has excellent thermal conductivity, so water boils quickly. Furthermore, the uneven surface, which was created by carefully hammering each groove with a hammer, increases the surface area, making this a masterpiece that further enhances the excellent thermal conductivity of copper.

In addition, the luster will increase over time, and the piece will become a rich, flavorful vessel with a mature appearance.

We deliver hammered copperware from Tsubame, Niigata, a town of artisans, made by artisans who have been hammering for three generations!

Copper ions enhance the aroma of tea!

Copper purifies water through the action of metal ions, and the boiled water also enhances the aroma of tea.

It's durable and can be used for a long time!

The base metal is thick, and by hammering it, the base metal is tightened and strengthened, making it very durable.

A lifetime item that becomes more mature the more you use it! The more you use hammered copperware, the more it will mature and develop a richer flavor.

The more you use hammered copperware, the more it will mature and develop a richer flavor.

In addition, this pot set has been treated with an oxidation coloring process on the surface to reduce the darkening that occurs due to natural oxidation, allowing you to enjoy a more subdued copper texture.

The process of making hammered copperware.

The process of making hammered copperware.

(1) Metal removal and cutting

Cut the copper plate to the appropriate size.

(2) Annealing

The copper plate is annealed in a fire.

(3) Launch

The annealed copper plate is hammered into shape using a variety of tools, including a metal backing, a wooden mallet, and a hammer.

(4) Annealing and firing

The copper plate hardens when hammered, so it is annealed and then hammered further to create the shape.

Repeat this process until the shape is complete.

(5) Molding

The finished shape is hammered to make the surface and shape even smoother (smoothing).

(6) Polishing and finishing

The surface is polished and then colored to finish it off. Kettles and copper pots are then tinned.

(7) Polishing , inspection, and completion

The product is polished, inspected, and then completed.

Care

When using for the first time after purchase and after each use, wash with a sponge and neutral kitchen detergent.

After washing, be sure to thoroughly wipe off any excess water with a cloth.

*If the inside of the pot is very dirty, wash it with a hard sponge (e.g. the hard part of a two-layer dishwashing sponge).

*Do not use metal scrubbers or abrasives.

Product data: Material

Pot: Copper, tin-plated/tin-plated (inner surface)

Brass (lid knob) / Grass vine wrap (main body handle)

Milk jug: Copper, tin-plated/tin-plated (inner surface)

Sugar bowl: Copper, tin-plated / tin-plated (inner surface) / brass (lid knob)

Spoon: Copper, tin-plated/tin-plated (inner surface)

*The handle of the lid will become hot while the pot is in use.

*Not compatible with induction or heating.

What is hammered copperware? Hammered copperware, meaning copperware struck and raised with a hammer, is a forging technique in which a single copper plate is repeatedly annealed and hammered with a variety of hammers, large and small, to create vessels. This technique was brought to Tsubame, Niigata, in the mid-Edo period and has been passed down and developed for around 200 years.

Hammered copperware, meaning copperware struck and raised with a hammer, is a forging technique in which a single copper plate is repeatedly annealed and hammered with a variety of hammers, large and small, to create vessels. This technique was brought to Tsubame, Niigata, in the mid-Edo period and has been passed down and developed for around 200 years.

Fukido was founded by the previous owner, Fujii Tomiji, in 1945. Since then, the second and third generations, Fujii Hiroshi and Fujii Ken, have been producing hammered copperware in Tsubame City, Niigata Prefecture, for three generations. The beauty of the shapes and diverse patterns created by Fujii's careful handwork is outstanding, and his high level of skill has led to the company receiving numerous awards.

・Niigata Prefecture Lifestyle and Culture Creative Industry Promotion Association IDS Design Competition IDS Encouragement Award (1995)

・Niigata Prefecture Recommended Excellent Product Special Award (1995)

・Niigata Prefecture Tsubame City Product Design Competition Encouragement Award (1996)

・Niigata Prefecture Lifestyle and Culture Creative Industry Promotion Association IDS THE BEST C Division 2nd Place (2000)

・Niigata Industrial Creation Organization IDS Design Competition IDS Encouragement Award (2006)

Each piece is handcrafted, carefully hammered with a hammer and chisel, with the user's joy in mind.

I would be happy if users could experience the ease of use, durability, and warmth that mass-produced products do not offer.

Size: Pot: Diameter 11.8cm (excluding handle and spout) x Height 13cm / Bottom thickness 1.0mm / Full capacity 0.9L Sugar bowl: Diameter 7.6cm x Height 7.5cm Milk bowl: Diameter 6.8cm x Height 5.3cm Spoon: Length 11.5cm

Weight: Pot: 520g<BR>Sugar bowl: 160g<BR>Milk bowl: 110g<BR>Spoon: 20g<BR>*As these are handmade, there may be slight differences in the dimensions and weight shown.<br> *Not suitable for induction or heating.